Many companies in Germany are facing a common problem: high prices for electricity and gas. Across all sectors, German companies are confronted with rising energy prices that not only affect their profitability but also threatens their long-term competitiveness.

Energy costs in Germany are among the highest in Europe. It is therefore becoming increasingly clear that companies need to take active measures to counteract the rising costs. In addition to the economic pressure, however, there are also positive economic incentives: technologies such as electrical storage and PV systems, which were still expensive a few years ago and therefore hardly suitable for the purpose of cost savings, have become increasingly available and therefore cheaper in recent years.

The time is ripe to exploit existing optimization and savings potential.

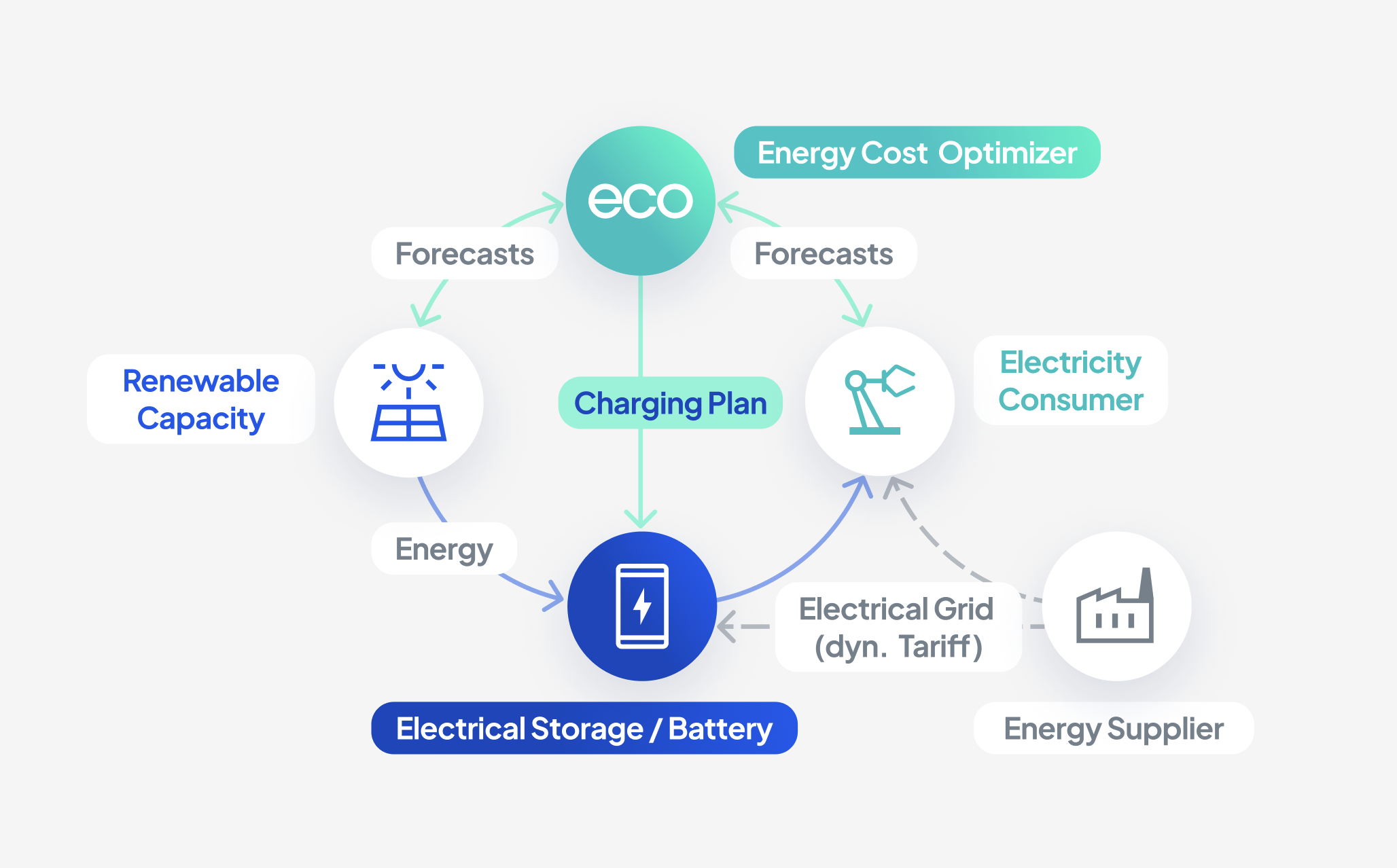

Urban Energy's philosophy is to accompany companies on their way to a sustainable future through digital and innovative solutions. From strategy and data collection to the implementation of suitable software, we combine sustainability with digitization along the entire value chain. That is why we have developed the Energy Cost Optimizer, or ECO for short, to help companies reduce their expenditure on electrical energy. ECO is a combination of the experience and technical expertise we have gained from successfully completed projects.

The origins

In a customer project, we were presented with the challenge of optimizing the use of a battery storage system connected to an industrial plant and thus increasing the financial savings potential.

Our idea was simple but effective: in addition to the consumption costs incurred for each kilowatt-hour consumed, many companies pay a performance price which, depending on the consumption profile, can account for up to 30% of the total electricity costs. The demand charge is based on the maximum power drawn from the grid over a quarter of an hour in a year. This quarter of an hour, in which the annual peak power is drawn, therefore determines a relevant proportion of the electricity bill. The average price per kWh of peak power is currently around €150 per year1. In addition to the savings from the reduced peak power, many companies can also achieve a discount on the grid fees through grid-friendly behavior.

The technical solution to this problem is called peak shaving. The basic idea behind peak shaving is that the electrical energy stored in the battery can be used so that at times of high energy demand, part of this demand can be met by using the battery rather than the grid. Discharging the battery thus reduces the effective electricity demand that has to be drawn from the grid.

The first step: Hybrid peak shaving

In addition to an electric storage battery, our customer also uses a locally installed PV system in order to reduce the annual peak output and therefore the power costs.

The integration of local production of renewable energy is known as hybrid peak shaving. This hybrid approach has been conceptually investigated in recent years, but actual working implementations are still rare. We have put the theoretical approach into practice and extended it with our own AI solutions.

A major challenge of hybrid peak shaving is that the integration of local renewable production significantly increases the economic potential on the one hand, but also increases the complexity of controlling the storage battery on the other.

Due to these problems, our most important optimization compared to previous peak shaving approaches is the use of daily forecasts of the expected electricity demand and the expected production of the PV system. Based on the forecasts, an optimized charging plan is generated for each day. On the one hand, this plan ensures that stored energy from the battery can be used optimally whenever the current power drawn from the grid exceeds the previous annual peak.

In addition, a charging plan can be used to ensure that whenever there is a surplus of PV electricity production, this can also be charged into the battery and does not have to be fed into the grid.

This has enabled us to achieve a significant improvement over current state-of-the-art solutions.

The evolution: Energy Cost Optimizer (ECO)

We developed ECO based on the experience gained in our customer project. The most important learning was that although we were able to optimize the power price, the storage used was not fully required on many days of the year. This is due to the fact that peak loads rarely occur in most industrial applications and optimization to reduce them is therefore not necessary on a regular basis. However, in order to justify the comparatively high initial costs of an electrical storage system, it should be used to its full potential wherever possible.

ECO is therefore not only able to reduce power costs, but also to optimize consumption costs. The prerequisite for this is the integration of intraday electricity price forecasts.

Based on the knowledge of the expected development of the electricity price, the battery can be charged when electricity is particularly cheap or even free. Conversely, the battery is discharged when prices skyrocket. This allows ECO to make optimum use of dynamic electricity tariffs. However, the most important lever for reducing energy costs remains the minimization of power costs.

Optimizing consumption costs only comes to the fore when peak loads are unlikely or only occur for a short time.

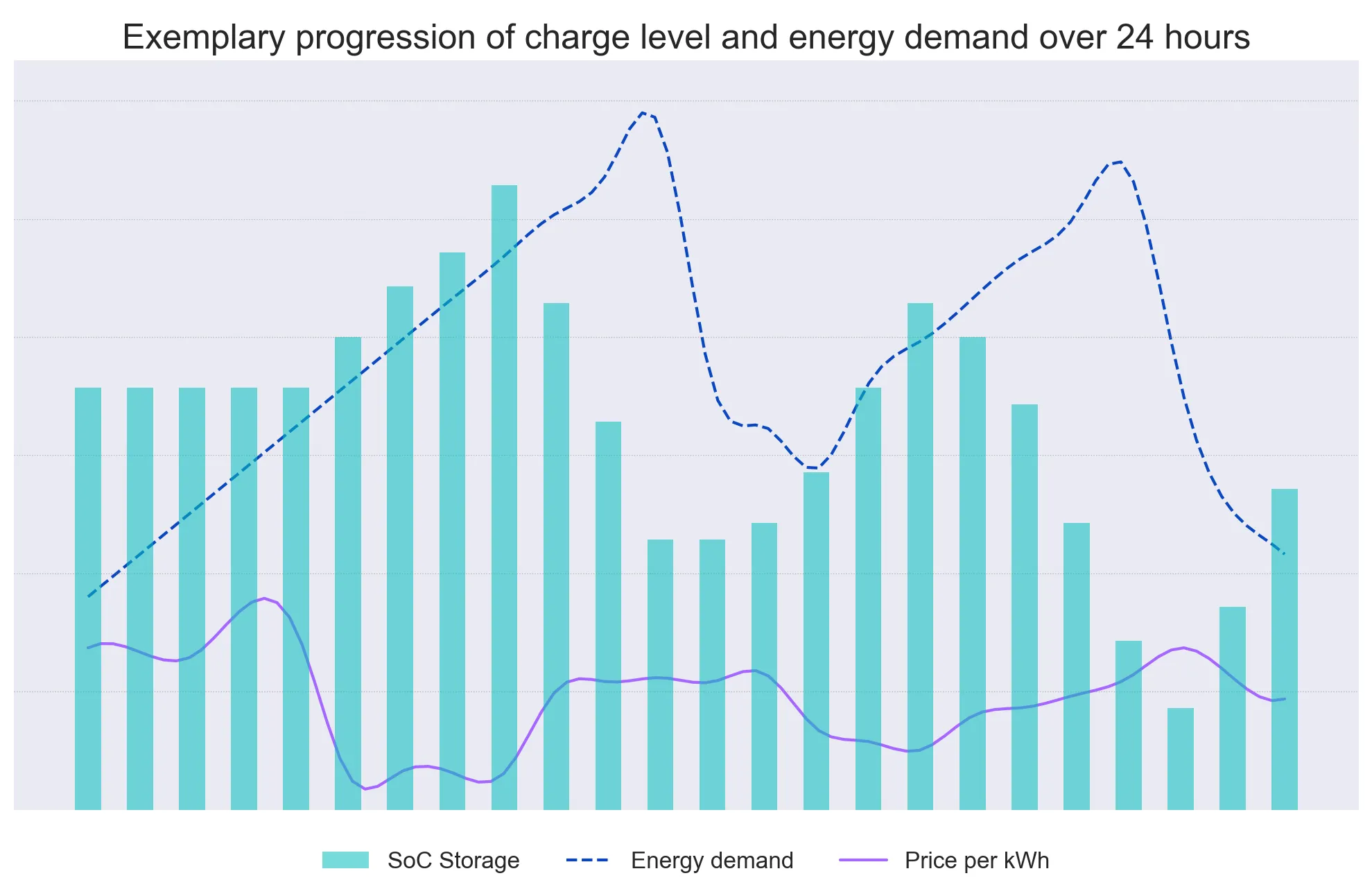

The simulations we conducted with ECO showed that optimizing the performance costs alone does not fully exploit the potential of a storage solution. The graph below shows an example of how the battery storage system is used over 24 hours. The turquoise columns show the current charge level of the battery. At times when the current price per kilowatt-hour consumed is low, the battery is charged and then discharged again as soon as prices rise again.

In addition, we validated ECO with a range of different freely available data sources. This showed that the optimizations implemented are capable of significantly reducing both performance costs and consumption costs. Two representative examples are:

- Using the example of a bakery with connected sales and an annual consumption of 15,000 kWh per year, the power costs could be reduced by 20% compared to conventional peak shaving. This saving in power costs corresponds to an effective monetary saving of around €9,000 per year. A 50 kWh battery was used in this scenario. Compared to conventional peak shaving, no additional hardware was required, so the savings were achieved solely by optimizing the charging control.

- In an exemplary production plant in the paper industry with an annual consumption of 1,000,000 kWh per year, consumption costs were reduced by an average of 8 % in addition to power costs. The photovoltaic system used in this scenario with a nominal output of 50 kWh was optimized so that all surpluses could always be loaded into the battery. A battery with a capacity of 500 kWh was used in this scenario.

ECO from the inside and a look into the future

ECO is designed from the ground up as a modular application. The architecture is capable of performing simulations based on historical values as well as being used in a live application.

At its core, the following main components exist:

-

Forecasting models

Depending on the use case, ECO can use various machine learning methods to integrate forecasts. The specific methods, features and metrics can be optimized and adapted for each consumer and producer. Forecasts of energy demand, the production of any existing generators and the electricity price to be paid are required in order to use ECO effectively. -

Optimizer

An optimized charging plan is developed based on the forecasts. This contains a planned charging or discharging capacity for each time interval. A typical time interval is a quarter of an hour, but other intervals can also be used. -

Live Controller

This component interprets the charging plan at the time of its implementation. Since predictions about the future can never be completely accurate, this component is particularly important as a bridge between the theoretically optimal charging plan and the values actually realized. In practice, the actual communication with a battery management system (BMS) can also take place in this component.

In the future, we will continue to work on adapting the ECO concept to the diverse needs of different customers. To achieve this, ECO must be able to communicate with a wide range of components such as meters or control systems via increasingly widespread standard protocols.

Furthermore, we will continue to develop the Optimizer and the forecasts together with our customers based on the experience we have gained.

Current political and economic developments support our approach. Dynamic electricity tariffs are becoming more and more widespread and the optimization of one's own energy costs is increasingly becoming an important factor in mutual competition. We are convinced that investing in intelligent management of your own energy infrastructure today will offer decisive advantages for companies tomorrow.